-

Cut-to-length line for transformer laminationCTL series cut to length line for transformer lamination is special equipment for transformer lamination manufacturing.

-

Product Description

Introduction:

CTL series cut to length line for transformer lamination is special equipment for transformer lamination manufacturing.It can punch and shear sheets of all oblique joint cores,including side leg sheets,the yoke and central leg sheets.The silicon steel coil is punched and sheared to be certain shape and size of laminations,then be diverted and tidied for use in stacking.

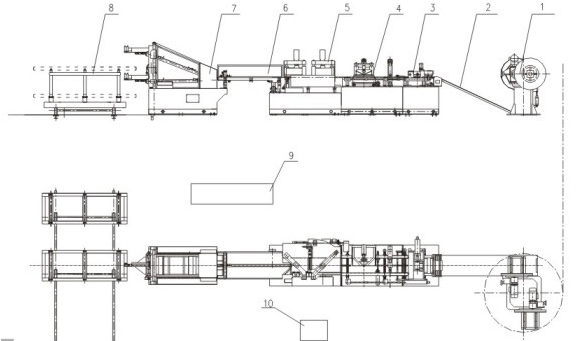

Composition:

1.Double decoiler; 2.Sheet guiding device; 3.Feeder; 4.Punching; 5.Shearing unit; 6.Discharge table; 7.Diverting mechanism; 8.Stacking trolley; 9.Control cabinet; 10.Operating console

Features:

1. Upgraded hydraulic system ensures no oil leakage at decoiler.

2.Electrical system uses Siemens products,including PLC,servo system and low voltage apparatus etc.Software program is optimized with addition functions of fault alarm and remote.

3.Key parts use excellent quality products,including key bearings,coupling,locknuts and belt etc.

4.All guide rail adopts carbide material.Guide rail service life doubles.

5.Strictly control parts producing process and parts quality.

6.Before ex-works,on load test is strictly followed with the machine,to ensure perfect operation at customer’s site.

Technical specifications:

Model

ParameterCTL400-22

CTL600-22

CTL900

Width of sheet (mm)

40-440

60-640

100-920

Length of sheet (mm)

300-2500

350-3500

500-5000

Thickness of sheet (mm)

0.20-0.35

Feeding speed (m/min)

0-214

0-214

0-180

Accuracy of cutting length (mm)

±0.1

Cutting burr (mm)

≤0.03

Accuracy of cutting angle

±0.01

Installed power (kW)

36

45

75

Compressed consumption (m3/min)

1.0

1.5

2

Outline dimensions (m)

12x4.9x2.2

15x5.2x2.3

27x12x3.4

E-mail:

E-mail:  Fax:

Fax:  Address:No. 88 Yongjin Road, High-end Park, Beichen District, Tianjin

Address:No. 88 Yongjin Road, High-end Park, Beichen District, Tianjin